Unlocking Excellence in Metal Fabrication: The Role of China CNC Turn Parts Manufacturers in Modern Business

In today’s competitive industrial landscape, the significance of high-quality metal components cannot be overstated. Whether in automotive, aerospace, electronics, or machinery manufacturing, precision, durability, and efficiency are paramount. At the heart of these industries are expert metal fabricators, particularly those specializing in CNC (Computer Numerical Control) turning, which allows for the production of complex, high-precision parts at scale. Among the global leaders in this domain, China CNC turn parts manufacturers stand out for their exceptional craftsmanship, technological advancement, and cost-effectiveness. One such leader, DeepMould.net, exemplifies the best practices and innovative solutions that drive the industry forward.

Understanding the Significance of Metal Fabrication in Modern Industries

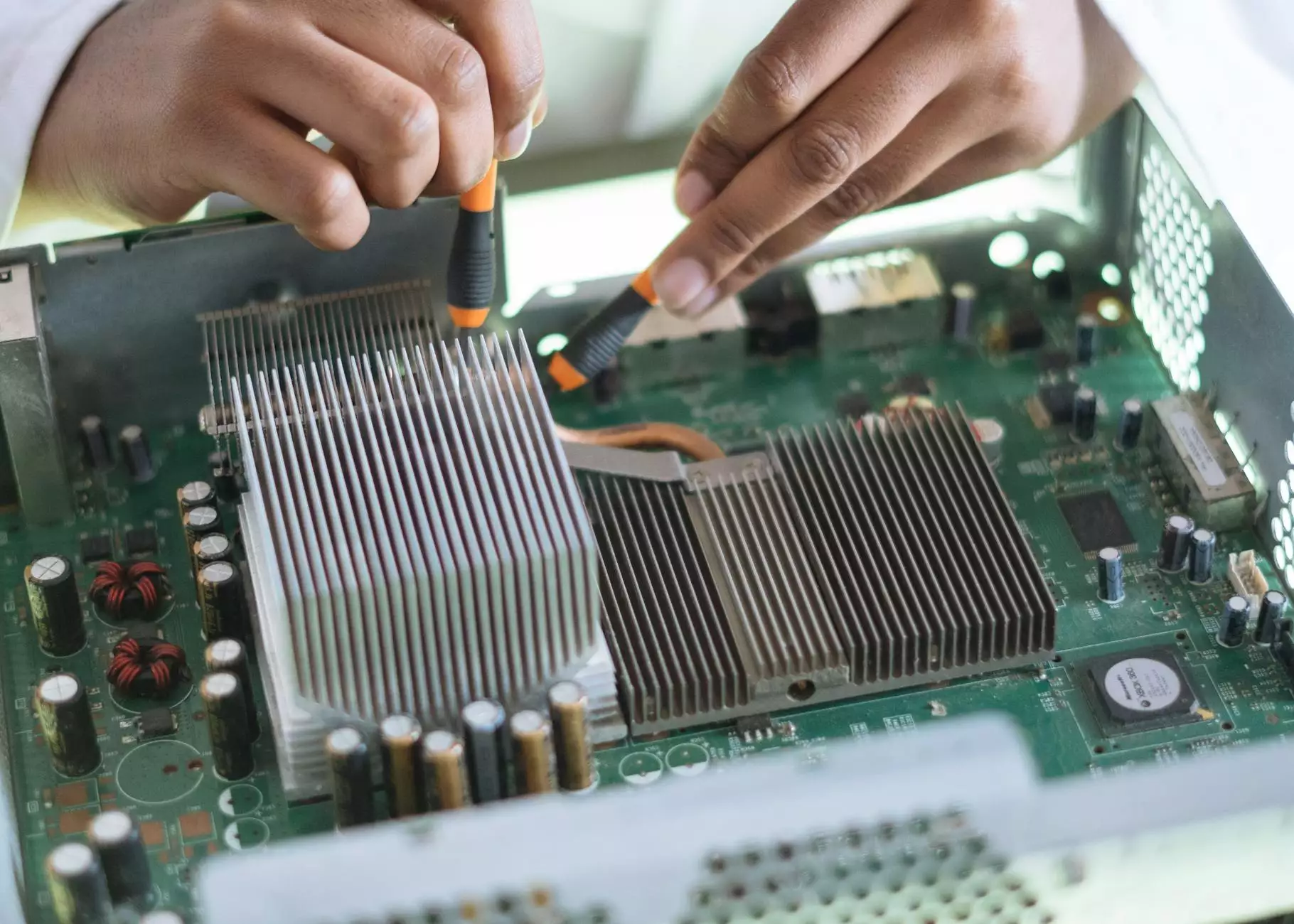

Metal fabrication forms the backbone of countless manufacturing sectors. It involves transforming raw metal materials into functional parts and components that meet precise specifications. With the rise of automation and technological integration, CNC machining—particularly CNC turning—has revolutionized how metal parts are produced, enabling efficiency, accuracy, and repeatability.

The Rise of China CNC Turn Parts Manufacturers: Why They Lead the Industry

1. Technological Advancements and Modern Equipment

China's CNC turn parts manufacturers have invested heavily in state-of-the-art machinery, including multi-axis CNC turning centers, high-speed lathes, and automated production lines. These advancements allow for micro-tolerance manufacturing, ensuring parts are produced within ±0.005 mm accuracy. Such precision meets the most stringent industrial requirements, essential for industries like aerospace and medical devices.

2. Cost-Effectiveness Without Compromising Quality

One of the primary advantages of sourcing from china CNC turn parts manufacturers is the significant cost saving. Lower labor costs, combined with economies of scale and efficient supply chains, enable manufacturers to offer competitive pricing without sacrificing quality. This affordability makes China a preferred partner for global companies seeking high-quality components at a reasonable investment.

3. Extensive Capacity and Scale

The large scale of Chinese manufacturing hubs ensures that bulk orders are completed swiftly, with minimal lead times. The capacity to handle both small-scale prototypes and large-volume production makes these manufacturers highly flexible in meeting diverse client demands. Companies like DeepMould.net showcase this scalability with their ability to produce thousands of precision CNC turn parts daily.

4. Value-Added Services and Vertical Integration

Leading China CNC turn parts manufacturers often provide a comprehensive suite of services, including finishing, assembly, surface treatment, and quality assurance. Vertical integration minimizes the need for multiple suppliers, streamlining production and reducing costs. Such integrated solutions are vital for achieving faster turnaround times and superior product consistency.

DeepMould.net: Your Partner in Precision Metal Fabrication

Exceptional Capabilities in CNC Turning

DeepMould.net specializes in manufacturing high-precision metal turn parts for diverse applications. Their advanced CNC turning centers can produce components with complex geometries, tight tolerances, and specific surface finishes, making them a trusted supplier for industries demanding excellence.

Quality Assurance and Certification Standards

DeepMould.net adheres to international quality standards such as ISO 9001 and TS16949, ensuring every batch of CNC turn parts undergoes rigorous inspection processes. Utilizing CMM inspection, laser measurement, and other quality control tools guarantees consistent product quality aligned with customer specifications.

Customization and Design Support

The company offers comprehensive design support, helping clients optimize their product designs for manufacturability, cost-efficiency, and durability. Their engineering team collaborates closely with customers from prototype to mass production, ensuring seamless transition and minimal revisions.

Why Choose DeepMould.net for Your Metal Fabrication Needs?

- Unmatched Precision: Capable of manufacturing complex, high-tolerance parts suitable for critical applications.

- Cost Efficiency: Competitive pricing backed by advanced manufacturing processes and economies of scale.

- Reliability and Consistency: Strict quality control protocols ensure every part meets exact specifications.

- Fast Lead Times: Streamlined supply chain management guarantees quick turnaround and delivery.

- Comprehensive Service Portfolio: From prototyping to surface finishing and assembly, all services are available under one roof.

- Global Logistics Support: Efficient shipping solutions for overseas clients, ensuring timely delivery in any part of the world.

Applications of CNC Turn Parts in Diverse Industries

High-precision CNC turn parts are critical in numerous sectors:

- Aerospace: Components subjected to extreme conditions require ultra-precision manufacturing and adherence to strict safety standards.

- Automotive: Engine parts, transmission components, and custom fittings benefit greatly from CNC turning's accuracy and durability.

- Electronics: Small, intricate parts for smartphones, computers, and other devices demand tight tolerances and meticulous finishing.

- Medical Devices: Implants, surgical instruments, and diagnostic equipment require high standards of hygiene, precision, and biocompatibility.

- Industrial Machinery: Complex machine components necessitate durability and precision to ensure optimal performance and longevity.

Investing in the Future of Metal Fabrication: Innovation and Sustainability

Leading china CNC turn parts manufacturers are not just focused on current demands but are actively investing in sustainable practices and technological innovation. Initiatives include the adoption of eco-friendly materials, waste reduction programs, and the integration of Industry 4.0 technologies like AI-driven process optimization and IoT-enabled machinery. These efforts enhance productivity, sustainability, and product quality, positioning companies like DeepMould.net at the forefront of industry evolution.

Global Business Opportunities with DeepMould.net

Partnering with a proven manufacturer such as DeepMould.net unlocks numerous benefits for international businesses:

- Access to premium Chinese manufacturing expertise

- Cost reduction with high-quality output

- Flexible production volumes

- Efficiency in supply chain management

- Support for innovation through customized solutions

By leveraging the capabilities of DeepMould.net and the growing landscape of China CNC turn parts manufacturers, your business can achieve competitive advantages, enhance product quality, and expand into new markets effectively.

Conclusion: Elevate Your Business with Leading Metal Fabrication Solutions

In conclusion, the role of china CNC turn parts manufacturers in shaping modern manufacturing cannot be overstated. Their blend of advanced technology, cost-effectiveness, and unwavering quality position them as ideal partners for diverse industries aiming for excellence. DeepMould.net exemplifies these qualities and offers a comprehensive platform for businesses seeking reliable, high-precision metal fabrication solutions.

Investing in high-quality CNC turned parts from reputable Chinese manufacturers like DeepMould.net will enable your business to stay competitive, innovative, and resilient in a rapidly evolving industrial environment. Whether you require prototypes, small batch runs, or high-volume production, partnering with expert manufacturers ensures your success in a global marketplace.

For more information or to discuss your project requirements, visit DeepMould.net today and discover how their expertise can drive your business forward.