The Might of Jabar Silicone: Revolutionizing Electronics and Medical Supplies

In today's fast-paced world, innovation in industrial materials plays a pivotal role in driving progress across various sectors. One of the powerful materials contributing to this innovation is silicone. Specifically, the emergence of Jabar Silicone has become a game-changer in the fields of electronics and medical supplies. This article delves deep into the many facets of Jabar Silicone, showcasing its applications, benefits, and potential for future developments.

Understanding Silicone: A Versatile Material

Silicone is a synthetic material made from silicon, oxygen, carbon, and hydrogen. Known for its flexibility, durability, and resistance to extreme temperatures, this material has become a staple in various industries. Its unique chemical structure allows it to withstand harsh environmental conditions while maintaining high performance, making it ideal for sensitive applications.

Properties of Silicone

- Thermal Stability: Silicone remains stable across a wide temperature range, from -60°C to +250°C, making it perfect for high-temperature applications.

- Chemical Resistance: It resists water, oxidation, and a variety of chemicals, which enhances its lifespan in diverse environments.

- Flexibility and Malleability: Silicone can be molded into intricate shapes and maintains flexibility, offering design versatility.

- Electrical Insulation: Its excellent electrical insulating properties are crucial in electronic applications.

- Biocompatibility: Silicone's non-toxic nature makes it suitable for medical applications, where safety is paramount.

The Birth of Jabar Silicone

Jabar Silicone represents not just a brand but a vision of excellence in the silicone industry. With a focus on quality, Jabar Silicone has established itself as a provider of top-tier silicone products tailored for the electronics and medical supplies sectors. The name “Jabar,” meaning powerful or mighty in Arabic, encapsulates the resilience and effectiveness of silicone as a material.

Why Choose Jabar Silicone?

When it comes to selecting a silicone supplier, reliability, and quality are of utmost importance. Here’s why Jabar Silicone stands out:

- Innovative Solutions: Jabar Silicone invests heavily in research and development, ensuring their products integrate the latest technological advancements.

- Customized Products: Recognizing that every application is unique, they offer tailored solutions to meet specific client needs.

- Commitment to Quality: Each product undergoes rigorous testing to ensure it meets both national and international standards.

- Sustainability: Jabar Silicone places an emphasis on environmentally friendly practices, using sustainable methods in their production process.

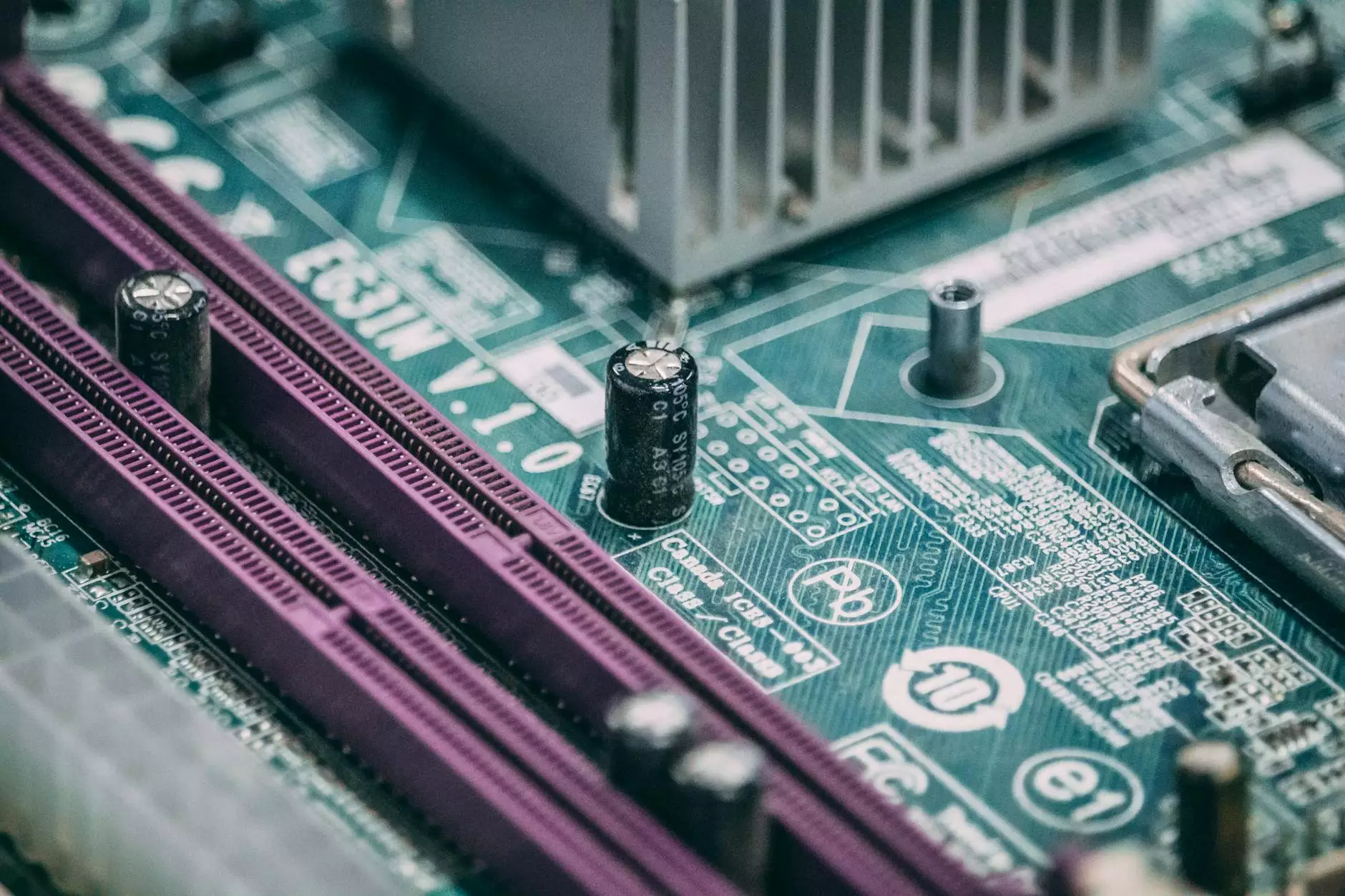

Applications of Jabar Silicone in Electronics

The electronics industry is a rapidly evolving landscape that demands materials capable of meeting increasingly sophisticated technological challenges. Here are some key applications of Jabar Silicone in this sector:

1. Seals and Gaskets

Jabar Silicone's durability makes it an ideal choice for producing seals and gaskets used in various electronics. These components are vital for preventing moisture and dust from damaging sensitive electronic parts.

2. Insulation Materials

Electrical insulation is essential in electronics to ensure safety and performance. Jabar Silicone products serve as excellent insulators, protecting devices from electrical faults and enhancing overall reliability.

3. Molding Applications

The customizability of Jabar Silicone allows for the creation of intricate components, such as cases and housings for electronic devices, ensuring protection while maintaining aesthetic appeal.

4. Adhesives and Sealants

Jabar Silicone provides powerful adhesives that enhance the integrity of electronic assemblies, ensuring components are securely bonded while remaining flexible under stress.

Applications of Jabar Silicone in Medical Supplies

In the medical field, where safety and efficacy are critical, Jabar Silicone has carved a niche with its high-quality products. Below are some notable applications:

1. Medical Devices

Many medical devices are made with Jabar Silicone due to its biocompatibility. From catheters to wearable devices, silicone ensures patient safety while providing reliable performance.

2. Molds for Prosthetics

The ability to create precise molds makes Jabar Silicone a go-to material in the production of prosthetics, where comfort and fit are paramount for the user’s quality of life.

3. Sealants in Pharmaceutical Packaging

Ensuring the integrity of pharmaceuticals is critical. Jabar Silicone’s sealants provide secure packaging that protects the efficacy of medical products throughout their shelf life.

4. Silicone Rubber for Surgical Applications

Jabar Silicone is frequently employed in the production of surgical tools and aids, offering flexibility and performance that meets the rigorous demands of the surgical environment.

The Benefits of Using Jabar Silicone

Embracing Jabar Silicone translates into a myriad of benefits for businesses in both the electronics and medical sectors. Here are some advantages:

- Enhanced Durability: Jabar Silicone products withstand wear and tear, reducing maintenance cycles and replacement costs.

- Safety Assurance: Their biocompatible products enhance safety in medical applications, ensuring patient welfare is prioritized.

- Operational Efficiency: The reliability of Jabar Silicone materials leads to more efficient operations in manufacturing and product longevity.

- Competitive Edge: Companies using Jabar Silicone can market their products as high-quality and innovative, attracting discerning customers.

Future of Jabar Silicone and Industry Trends

As the demand for high-performance materials continues to rise, the future of Jabar Silicone appears robust. Trends shaping the industry include:

1. Advancements in Silicone Technology

The continuous development of silicone technology, such as high-temperature resistance and biocompatibility improvements, will keep Jabar Silicone at the forefront of material innovation.

2. Sustainable Practices

With an increasing focus on sustainability, Jabar Silicone will likely enhance its eco-friendly practices, appealing to environmentally conscious consumers and businesses alike.

3. Integration of Smart Technology

The rise of wearable technology and smart devices will create an exponential demand for silicone materials tailored for flexibility and durability, areas where Jabar Silicone excels.

4. Global Expansion

With the global demand for electronics and medical supplies on the rise, Jabar Silicone is poised for international market expansion, tapping into emerging markets and sectors.

Conclusion: Embracing the Power of Jabar Silicone

In conclusion, the introduction of Jabar Silicone into the electronics and medical supplies industries has set a new benchmark for quality and innovation. Its array of applications, combined with its superior properties, positions Jabar Silicone as a leading choice among manufacturers. As we look to the future, the ongoing commitment to excellence and sustainability will undoubtedly allow Jabar Silicone to maintain its status as a powerful force in the industry.

Those seeking reliable, high-performance materials for their operations should explore the capabilities offered by Jabar Silicone. The power of silicone, encapsulated in the Jabar brand, is not just a promise of durability and safety—it's a guarantee of quality enhanced through continuous innovation.