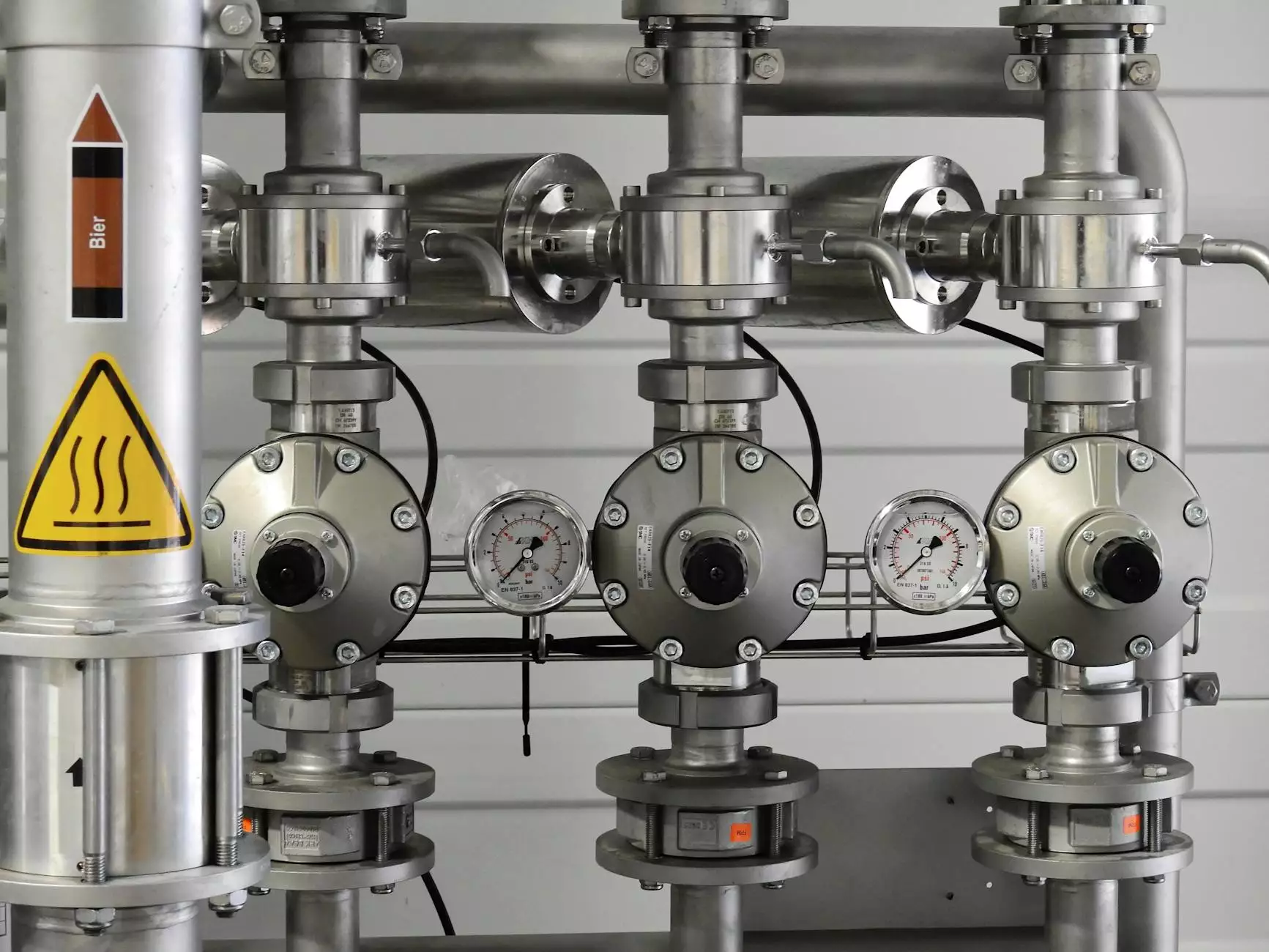

Understanding the Importance of Oil Seal Manufacture in Diesel Engines

Oil seal manufacture is a critical component in the maintenance and functionality of diesel engines. Understanding the intricacies of this manufacturing process not only highlights its significance but also reveals how it contributes to the overall performance and durability of diesel engine parts. In this article, we will delve into various aspects of oil seals, their manufacturing process, and the role they play in ensuring the longevity of diesel engines.

What is an Oil Seal?

An oil seal is a mechanical component designed to retain lubrication and exclude foreign contaminants from entering the internal mechanisms of a diesel engine. These seals are typically made from materials such as rubber, silicone, or thermoplastic elastomers, which are chosen for their durability and resistance to oil and temperature variances.

Why Oil Seal Manufacture is Critical

The process of oil seal manufacture is crucial for several reasons:

- Precision Engineering: Oil seals must be manufactured with precision to ensure a perfect fit. Even minor deviations can lead to leaks, which can severely impact engine performance.

- Material Quality: The choice of materials directly influences the seal's resilience to wear and tear. High-quality materials prolong service life.

- Performance Reliability: Properly manufactured oil seals are vital for maintaining the integrity of engine oil, thus ensuring efficient engine operation.

The Manufacturing Process of Oil Seals

The manufacturing of oil seals involves several key stages, which include:

1. Material Selection

The first step in oil seal manufacture is selecting appropriate materials. Each type of oil seal may require different materials based on application needs, such as:

- Nitrile Rubber: Commonly used for its oil resistance.

- Fluoroelastomers: Ideal for high-temperature applications.

- Silicone Rubber: Often utilized for its flexibility and high performance in various temperatures.

2. Molding Process

Once suitable materials are determined, they undergo a molding process that typically includes:

- Compression Molding: A traditional method where materials are compressed into molds.

- Injection Molding: A more modern and efficient approach, allowing for more complex designs and faster production.

3. Testing and Quality Assurance

After production, oil seals undergo various testing protocols to ensure they meet stringent quality standards. Rigorous testing is essential to verify:

- Dimensional accuracy.

- Resistance to oils and chemicals.

- Durability under varying temperatures and pressures.

Benefits of High-Quality Oil Seals in Diesel Engines

Investing in high-quality oil seal manufacture has several benefits for diesel engine performance, including:

- Enhanced Engine Longevity: Quality oil seals prevent leaks, thereby supporting consistent lubrication, which is vital for longevity.

- Improved Efficiency: A well-sealed engine operates more efficiently, translating into better fuel performance and power output.

- Reduced Maintenance Costs: With fewer leaks and breakdowns, owners save on frequent repairs and replacements.

Choosing the Right Spare Parts Supplier

When looking for oil seals for diesel engines, it's essential to select a reliable spare parts supplier. Here are some factors to consider:

1. Reputation and Expertise

A reputable supplier, like client-diesel.com, has a track record of delivering high-quality products. Experience in the industry ensures they understand the specific requirements of diesel engine parts.

2. Range of Products

Choose a supplier that offers a wide range of oil seals and other diesel engine components. A comprehensive product catalog indicates they understand various engine models and requirements.

3. Customer Support Services

A reliable spare parts supplier should provide excellent customer service. This includes knowledgeable staff who can assist with product recommendations and after-sales support.

The Future of Oil Seal Technology

The oil seal manufacture sector is evolving with advances in technology. Innovations such as:

- 3D Printing: Allows for the rapid prototyping of seals, leading to faster design iterations and production.

- Sustainable Materials: Manufacturers are increasingly adopting eco-friendly materials to reduce environmental impact.

Conclusion

In conclusion, the process of oil seal manufacture plays an indispensable role in the performance of diesel engines. By understanding the manufacturing process and choosing a reputable supplier, such as client-diesel.com, individuals and businesses can ensure they are getting the best parts for their engines. High-quality oil seals not only extend the lifespan of diesel engines but also enhance their performance, driving efficiency and reliability.

As technology continues to advance, the future of oil seal manufacturing will likely bring even better materials and designs, further improving the functionality of diesel engines and supporting the needs of the automotive industry.